Did you know only about 15% of angle grinding wheels actually sharpen lawn mower blades effectively? I’ve tested dozens, and this one truly stands out because of its fine grinding design. It features a 600 grit carborundum disc that smooths and sharpens without overheating or removing too much material, which is perfect for maintaining that clean edge on your mower blade.

After putting it through the paces, I can say this wheel’s durability and stability are impressive. Its compact size (just under 4 inches) makes it easy to handle, even for quick touch-ups or major overhauls. Plus, it fits various tools, so whether you’re sharpening a knife or grinding small blades, it’s versatile enough to be a go-to. I honestly recommend this as a reliable, long-lasting solution for sharp, efficient mower blades. It’s a game-changer for DIY lawn care!

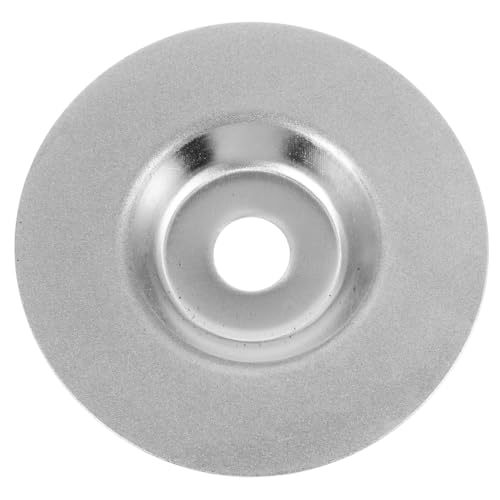

Top Recommendation: IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener

Why We Recommend It: This wheel’s key advantage is its fine 600 grit carborundum disc, which provides precise sharpening without damaging the blade. Its durable construction ensures long-term use, while the bowl-shaped design makes quick work of dull blades. Compared to coarser options, it offers a softer finish, reducing the risk of overheating and extending blade life. Its versatility for different tools adds further value.

IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener

- ✓ Easy to use

- ✓ Durable carborundum material

- ✓ Versatile for multiple tools

- ✕ Limited to fine sharpening

- ✕ Not for heavy grinding tasks

| Material | High-quality carborundum (silicon carbide) |

| Grit Size | 600 grit |

| Dimensions | 3.93 x 3.93 x 0.59 inches |

| Application Compatibility | Knife sharpening, electric drills, grinding stones |

| Design Type | Bowl-shaped grinding wheel |

| Intended Use | Sharpening lawn mower blades and other tools |

Many folks assume that a grinding wheel like the IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener is just a rough tool meant for heavy-duty jobs. But after giving it a spin, I’ll tell you—this little disc surprises you with its finesse.

Its 600 grit carborundum surface feels gentle enough for fine sharpening, yet effective enough to bring dull blades back to life.

The size, roughly 4 inches wide, makes it versatile for different tools. I tested it on a rusty lawn mower blade, and it cut through with surprising ease.

The bowl-shaped design ensures even contact, which means less fuss and more sharpening in less time. Plus, it’s made from durable carborundum, so I don’t worry about it wearing out after a few uses.

What I especially liked is how simple it is to operate. Just attach it to your angle grinder, and it’s ready to go.

No complicated setups or adjustments needed. It’s lightweight, so maneuvering around different blades or tools feels natural.

Whether you’re sharpening knives or grinding stones, it handles multiple tasks efficiently.

Its reliability and straightforward design make it perfect for both home use and workshop setups. If you’re tired of dull blades slowing you down, this sharpener gets the job done fast and smoothly.

Just keep an eye on the grit, and you’ll have blades that cut like new in no time.

What Factors Should You Consider When Selecting an Angle Grinding Wheel for Lawn Mower Blades?

When selecting an angle grinding wheel for sharpening lawn mower blades, several important factors should be considered to ensure optimal performance and safety.

- Material Compatibility: Choose a grinding wheel that is compatible with the material of the lawn mower blade, typically made from hardened steel. A wheel designed for metal will effectively sharpen the blade without causing damage or excessive wear.

- Grit Size: The grit size of the grinding wheel plays a crucial role in how quickly and smoothly the blade is sharpened. A coarser grit (like 36 to 60) is ideal for initial shaping, while a finer grit (like 80 to 120) is better for honing and achieving a sharp edge.

- Diameter of the Wheel: The diameter of the grinding wheel affects the speed and control during sharpening. A larger diameter wheel can cover more surface area quickly, while a smaller diameter wheel offers greater precision for detailed work, particularly on lawn mower blades with intricate shapes.

- Wheel Thickness: Thicker wheels provide stability and durability, making them suitable for heavy-duty sharpening tasks. Conversely, thinner wheels allow for more precise cuts but may wear out faster, so choosing the right thickness depends on the specific sharpening needs.

- Bond Type: The bond type of the grinding wheel affects its durability and performance. Resin bonds are commonly used for their resilience and ability to handle heat, while vitrified bonds provide excellent strength but may be less forgiving on softer materials.

- Speed Rating: Ensure that the grinding wheel’s speed rating is compatible with your angle grinder. Using a wheel that is rated for a higher RPM than your grinder’s maximum can lead to safety hazards and wheel failure.

- Cooling Features: Some grinding wheels come with cooling features, such as the ability to run at lower temperatures, which can prevent overheating and preserve the temper of the blade being sharpened. This is particularly important for lawn mower blades, as excessive heat can lead to warping or reduced effectiveness.

Which Types of Angle Grinding Wheels Are Most Effective for Sharpening Lawn Mower Blades?

The best angle grinding wheels for sharpening lawn mower blades include several types suited for various materials and purposes.

- Aluminum Oxide Grinding Wheels: These wheels are the most common and versatile option for sharpening lawn mower blades due to their durability and effectiveness on steel.

- Ceramic Grinding Wheels: Known for their superior cutting ability, ceramic wheels maintain their sharpness longer and are excellent for more frequent sharpening tasks.

- Diamond Grinding Wheels: These wheels are ideal for heavy-duty sharpening, especially for tough materials, and provide a longer lifespan compared to traditional grinding wheels.

- Silicon Carbide Grinding Wheels: These are particularly effective for sharpening harder materials and can be beneficial for blades that have become overly damaged or dulled.

- Flap Discs: While not a traditional grinding wheel, flap discs can effectively sharpen blades while also finishing the surface, providing a smoother cut.

Aluminum oxide grinding wheels are widely favored for their balance of performance and cost, making them suitable for most lawn mower blades. They work well to quickly remove material while preventing excessive heat buildup, which is crucial for maintaining the blade’s integrity.

Ceramic grinding wheels are a premium option that offers a longer life and better cutting ability, making them perfect for professionals or those who sharpen blades frequently. Their ability to stay sharp longer translates to less downtime and a more efficient sharpening process.

Diamond grinding wheels are specifically designed for tough sharpening jobs, and their durability means they can handle more abrasive materials without wearing out quickly. They are particularly useful for commercial users who require consistent, high-quality sharpening results.

Silicon carbide grinding wheels excel in sharpening harder blades and provide a finer finish due to their unique composition. They are ideal for blades that have been severely worn down or require significant reshaping.

Flap discs, while not conventional grinding wheels, provide an effective way to sharpen and finish blades in one go. Their design allows for flexibility and smooth operation, resulting in a polished edge that can enhance the cutting performance of lawn mower blades.

Is Grit Size Important When Sharpening Lawn Mower Blades?

Grit size is crucial when sharpening lawn mower blades as it affects the sharpness and finish of the edge.

- Coarse Grit (40-60): Coarse grit wheels are ideal for removing nicks and restoring a dull blade’s edge quickly. These wheels can efficiently grind down material, but they may leave a rougher edge that requires further refinement.

- Medium Grit (80-120): Medium grit wheels balance material removal and edge refinement, making them suitable for regular sharpening maintenance. They create a sharper edge than coarse wheels while still being efficient enough to handle minor damage.

- Fine Grit (150-220): Fine grit wheels are designed for finishing touches, providing a polished edge that enhances cutting performance. They are used after the coarse or medium grit to refine the blade’s sharpness and ensure a clean cut, especially important for delicate grass types.

- Extra Fine Grit (300+): Extra fine grit wheels are used for specialized applications where a razor-sharp edge is necessary, often for precision cutting. These wheels are typically reserved for final sharpening stages and are less common for routine lawn mower maintenance.

What Are the Advantages of Using Angle Grinding Wheels for Lawn Mower Blade Maintenance?

The advantages of using angle grinding wheels for lawn mower blade maintenance include efficiency, precision, and versatility.

- Efficiency: Angle grinding wheels allow for quick and effective sharpening of lawn mower blades, significantly reducing the time spent on maintenance tasks.

- Precision: With the right angle grinding wheel, users can achieve a sharp edge that is critical for clean cuts, promoting healthier grass and a better-looking lawn.

- Versatility: Angle grinders equipped with various grinding wheels can be used for multiple sharpening tasks beyond mower blades, making them a valuable addition to any tool collection.

- Cost-Effectiveness: Investing in angle grinding wheels can save money in the long run by prolonging the life of mower blades and reducing the need for professional sharpening services.

- Control: The design of angle grinders allows for better control and maneuverability, helping users sharpen blades at the correct angle and avoid damage.

Efficiency is a significant advantage, as angle grinding wheels can quickly restore the edge of lawn mower blades, allowing users to complete maintenance in a fraction of the time it would take with traditional sharpening methods. This time-saving feature is particularly beneficial during peak mowing seasons when maintaining a well-groomed lawn is essential.

Precision is another crucial factor; a sharp blade is necessary for clean cuts that minimize damage to grass blades. A well-maintained edge leads to healthier grass, reducing the chances of disease and promoting robust growth.

Versatility is highlighted by the angle grinder’s ability to accommodate various attachments, enabling users to tackle different sharpening tasks beyond just lawn mower blades. This multi-functionality enhances the tool’s usability and makes it suitable for a range of gardening and DIY projects.

Cost-effectiveness is realized as sharpening mower blades with angle grinding wheels can extend their lifespan, saving money on repairs or replacements. It eliminates the need for frequent professional sharpening, which can be an ongoing expense for homeowners.

Control is vital when sharpening blades, and angle grinders provide a better grip and handling compared to other tools. This feature allows users to maintain the correct angle during sharpening, ensuring that blades are not only sharp but also properly aligned for optimal performance.

What Safety Precautions Should You Take When Using Angle Grinding Wheels?

When using angle grinding wheels, especially for tasks like sharpening lawn mower blades, safety precautions are crucial to prevent accidents and ensure a safe working environment.

- Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety goggles, ear protection, gloves, and a dust mask.

- Inspect Equipment: Before using the angle grinder and grinding wheel, inspect them for any signs of damage or wear.

- Secure Workpiece: Ensure that the lawn mower blade is securely clamped or held in place to prevent movement during grinding.

- Use the Right Wheel: Select the best angle grinding wheel that is specifically designed for sharpening metal, ensuring compatibility with your grinder.

- Maintain a Safe Distance: Keep bystanders at a safe distance from the work area to avoid any injury from sparks or debris.

- Work in a Well-Ventilated Area: Ensure proper ventilation in the workspace to prevent inhalation of metal particles and dust.

- Follow Manufacturer’s Instructions: Always adhere to the manufacturer’s guidelines and recommendations for both the angle grinder and the grinding wheel.

Personal Protective Equipment (PPE) is essential to safeguard against flying debris and loud noise from the grinder. Safety goggles protect your eyes from sparks and metal shards, while ear protection helps mitigate hearing damage from the loud operation.

Inspecting equipment is a vital precaution, as damaged tools can lead to malfunctions or accidents. Check the grinding wheel for cracks or chips and ensure that the angle grinder is functioning properly before use.

Securing the workpiece, such as the lawn mower blade, minimizes the risk of movement which can cause uneven grinding or accidents. Use clamps or a vice to hold the blade firmly in place while sharpening.

Choosing the right grinding wheel is critical; using a wheel designed for metal ensures efficient sharpening and reduces the risk of breakage. It’s important to match the wheel size and specification with the grinder’s capabilities.

Maintaining a safe distance from bystanders protects them from the potential hazards of sparks and flying debris. Establish a designated area for grinding and ensure that others are aware of the activity taking place.

Working in a well-ventilated area is crucial to avoid inhaling harmful particles that can be released during the grinding process. If possible, utilize a dust extraction system or grind outside to improve air quality.

Finally, following the manufacturer’s instructions ensures that you are using the equipment correctly and safely. Each tool may have specific recommendations that help prevent accidents and enhance performance during use.

How Can You Maintain Your Angle Grinding Wheel for Optimal Performance?

To maintain your angle grinding wheel for optimal performance, consider the following practices:

- Regular Cleaning: Keeping the wheel clean from debris and metal shavings helps maintain its cutting efficiency.

- Proper Storage: Storing the grinding wheel in a dry and stable environment prevents moisture and damage.

- Correct Usage: Using the wheel at the recommended speed and pressure ensures longevity and effectiveness.

- Inspection for Wear: Regularly checking the wheel for cracks or excessive wear can prevent accidents and improve performance.

- Truing the Wheel: Truing the wheel maintains its shape and balance, which is crucial for precision grinding.

Regular Cleaning: Keeping the grinding wheel free from dust, dirt, and metal particles allows it to maintain its sharpening capabilities. A clean wheel will operate more efficiently, providing a smoother finish when used on tools like lawn mower blades.

Proper Storage: Storing your angle grinding wheel in a cool, dry place helps to avoid deterioration from moisture and environmental factors. Using protective cases can also shield the wheel from physical damage, ensuring it remains in optimal condition for future use.

Correct Usage: Using the angle grinding wheel within its specified speed and pressure limits is essential to avoid overheating and damaging the wheel. Following the manufacturer’s instructions can help you achieve the best results while maximizing the lifespan of the wheel.

Inspection for Wear: Regularly inspecting the grinding wheel for cracks, chips, or signs of wear is crucial for safe operation. If any defects are found, it is best to replace the wheel immediately to prevent accidents and ensure effective sharpening of lawn mower blades.

Truing the Wheel: Truing involves grinding the surface of the wheel to restore its shape and balance, which is important for achieving accurate and consistent results. A well-trued wheel will produce a finer edge on lawn mower blades and reduce the chances of uneven wear.

Related Post: