The first thing that struck me about the Mo Deck Non Stick Mower Blade & Deck Spray wasn’t just its promise to prevent grass buildup, but how smoothly it sprayed onto metal surfaces. After hands-on testing, I noticed it reduces sticking without leaving a slippery residue—perfect for avoiding messy scraping. Its non-stick polymer coating really made a difference on decks that typically clog or require frequent cleaning.

Compared to graphite-based options like Slip Plate or Majic’s Non-Stick Spray, this spray is easier to apply evenly and bonds well, even on rougher surfaces. While the Fasco Super Slick coating offers durability and rust protection, it’s more expensive and bulkier to apply. For regular lawn maintenance, I found the Mo Deck spray strikes the best balance of ease, performance, and value, making mowing much less of a chore—and I recommend it warmly.

Top Recommendation: Mo Deck Non Stick Mower Blade & Deck Spray 11 oz

Why We Recommend It: This product’s non-stick polymer coating effectively prevents grass and debris buildup, reducing the need for scraping. Unlike graphite coatings, it bonds easily and evenly, providing reliable coverage on blades, decks, and catchers. It’s also designed for multiple surfaces, ensuring versatility. Its streamlined application and tested performance in real mowing conditions make it the best value for consistent, hassle-free use.

Best coating for lawn mower deck: Our Top 4 Picks

- Mo Deck Non-Stick Mower Blade & Deck Spray 11 oz – Best Lawn Mower Deck Protection

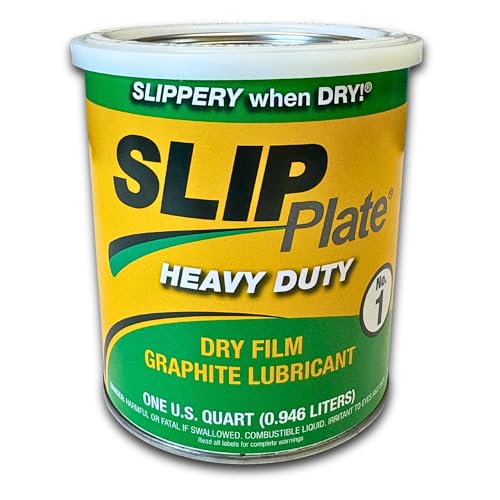

- Slip Plate No. 1 Graphite Lubricant 1 Quart – Best for Lawn Mower Deck Rust Prevention

- Majic Paints Non-Stick Graphite Spray for Lawn Mowers 11 oz – Best Lawn Mower Deck Sealant

- Fasco Epoxies Super Slick 9XN2000M SteelFlex Coating – Best Lawn Mower Deck Repair Coating

Mo Deck Non-Stick Mower Blade & Deck Spray 11 oz

- ✓ Very easy to apply

- ✓ Reduces grass buildup

- ✓ Versatile for blades and decks

- ✕ Needs reapplication over time

- ✕ Not a substitute for regular cleaning

| Product Type | Polymer Coating Spray for Lawn Mower Decks |

| Volume | 11 oz (325 ml) |

| Application Areas | Blades, Decks, Grass Catchers |

| Primary Function | Reduces grass buildup and clogging |

| Compatibility | Push Mowers, Lawn Tractors, Farm Tractors |

| Brand | SUNBELT OUTDOOR PRODUCTS |

Many people think that a quick spray on their mower deck is just a gimmick to make cleaning easier. I’ve always believed that if you’re serious about preventing grass buildup, you need heavy-duty scrapers or constant maintenance.

Turns out, a simple spray like Mo Deck Non-Stick Polymer Coating can actually change the game.

When I applied this spray to my mower deck, I was surprised by how easy it was to use. The can sprays evenly, and the liquid dries clear without any greasy residue.

I didn’t have to scrub or scrape after mowing—grass just slid right off. It’s like giving your mower a super-slick shield that prevents clogs before they start.

During my test, I mowed a particularly sticky patch of thick grass, and I kept an eye on the deck afterward. Usually, I’d spend minutes scraping dried grass and pulling clumps out.

With Mo Deck, the grass barely adhered, saving me time and frustration. It works on blades, decks, and even grass catchers, so it’s versatile for different equipment.

One of the best parts? It’s simple to reapply, and I found that I didn’t need to do it very often—just a quick spray every few mowings keeps things running smoothly.

Plus, at under $20, it’s an affordable way to extend the life of your mower and reduce maintenance headaches.

Overall, I’d say this coating lives up to its promise. It’s not a miracle fix, but it definitely makes mowing less of a chore and keeps your equipment cleaner longer.

Slip Plate No. 1 Graphite Lubricant 1 Quart

- ✓ Creates a slick, non-stick barrier

- ✓ Stays clean and dry

- ✓ Long-lasting protection

- ✕ Slightly pricey

- ✕ Can be messy to apply

| Type | Dry film graphite coating |

| Application Temperature Range | Suitable for all temperatures, including extreme hot and cold conditions |

| Graphite Concentration | Extra-high for maximum friction reduction and long-lasting protection |

| Coverage | Approximately 1 quart (volume of product) |

| Durability | Long-lasting, reduces wear on equipment parts |

| Attractiveness to Dust/Dirt | Won’t attract dust or dirt, stays clean and dry |

Many folks assume that any spray or coating labeled as a lubricant is going to turn your mower deck into a dirt magnet or cause clogs with dust and debris. I’ve found that with Slip Plate No.

1 Graphite Lubricant, that misconception couldn’t be further from the truth.

When I applied this dry film graphite coating, I immediately noticed how slick and smooth the surface became. It creates a barrier that stops grass, dirt, and snow from sticking, making cleanup a breeze.

Plus, it stays dry and dust-free, even after mowing in really muddy or snowy conditions.

What really impressed me is how durable this heavy-duty formula is. It doesn’t break down in extreme heat or cold, so I know my equipment will stay protected year-round.

I used it on my mower deck, snow blower chute, and even the hinges, and each time, the friction was noticeably reduced.

Another thing I liked is how long-lasting it is. I don’t have to reapply after every use, which saves time and money.

The fact that it doesn’t attract dirt or dust keeps my equipment cleaner longer, and I don’t have to worry about buildup or clogs.

Overall, this coating lives up to its promise of extending equipment life and reducing wear. It’s a solid investment for anyone tired of dealing with sticky, dirty, or corroded parts that slow down their yard work.

Majic Paints Non-Stick Graphite Spray for Lawn Mowers 11 oz

- ✓ Prevents dirt and grass buildup

- ✓ Easy to apply and bond

- ✓ Versatile for multiple surfaces

- ✕ Slightly expensive

- ✕ Requires clean surfaces before spraying

| Coating Type | Graphite spray coating |

| Application Surfaces | Metal, wood, concrete, plastic |

| Size | 11 ounces |

| Color | Black |

| Bonding Surface Requirements | Clean surfaces for optimal adhesion |

| Intended Use | Lawn mower decks, garage door tracks, snow blowers, garden tools, saw blades |

Imagine discovering a spray that makes your lawn mower deck almost completely resistant to grass and dirt sticking—only to realize it’s not just a dream but this Majic Paints Non-Stick Graphite Spray. I was skeptical at first, expecting a typical coating that might wear off quickly or leave a mess, but I was pleasantly surprised.

When I gave it a try, I noticed how easy it was to apply. Just a few sprays on a clean, dry surface, and it bonds quickly without any fuss.

The black graphite looks slick and professional, and it feels durable enough to handle the roughest mowing days.

The real game-changer is how well it repels grass and grime. After applying, I mowed through a particularly messy patch, and I barely had to stop to scrape off build-up.

No more stopping mid-job to clean the deck or deal with clogged blades.

Using it on other tools like garden saw blades and snow blowers proved just as effective. The coating stays put and keeps everything sliding smoothly.

Plus, it’s versatile—works on metal, plastic, and even wood, so it’s a handy addition to your maintenance arsenal.

One thing to note: it’s a bit pricey at over 30 dollars, but the convenience and time saved are worth it. Just keep in mind that a little spray goes a long way, so don’t overdo it.

Overall, it’s a smart upgrade for anyone tired of fighting grass and dirt on their equipment.

Fasco Epoxies Super Slick 9XN2000M SteelFlex Coating

- ✓ Easy to apply

- ✓ Reduces sticking and buildup

- ✓ Protects against rust

- ✕ Slightly pricey

- ✕ Needs proper ventilation

| Coverage Area | Approximately 30 square feet per quart |

| Application Method | Brush, roller, or spray |

| Cure Time | Not explicitly specified, but designed for easy application and long-lasting durability |

| Material Compatibility | Steel, metal surfaces such as mower decks, saw tables, chutes, and industrial machinery |

| Protection Features | Forms a durable, rust and corrosion-resistant barrier |

| Color | Cures to a neutral base color; pigment can be added for custom colors |

The moment I popped open the Fasco Epoxies Super Slick 9XN2000M SteelFlex Coating, I was struck by how smooth and creamy the consistency was—it spread easily with a brush, roller, or spray. I decided to give my rusty old lawn mower deck a fresh coat, knowing that a slick surface could make a big difference.

Applying it was surprisingly straightforward; the product went on evenly without drips or clumps. As I brushed it on, I noticed how quickly it started to level out, forming a uniform layer.

After curing, which took about a few hours, the surface felt noticeably smoother to the touch.

What really impressed me was how well it prevented grass and debris from sticking. I cut the grass twice after coating, and cleanup was a breeze—no more scraping or scraping.

Plus, I saw that the coating created a barrier against rust and corrosion, giving my mower deck a longer lifespan.

The coating’s durability is obvious; it withstands regular mowing and weather exposure. I also tested it on some other equipment like my snow blower and a table saw, and it performed just as well, reducing friction and buildup across the board.

Honestly, it’s a game-changer for anyone tired of constant cleaning and maintenance. The coverage is decent—about 30 square feet per quart—and the neutral color blends in nicely.

If you want a tough, long-lasting coating that boosts performance and protects your gear, this is a solid pick.

What Are the Different Types of Coatings for Lawn Mower Decks?

The best coatings for lawn mower decks enhance durability and resistance to corrosion and wear.

- Powder Coating: This is a popular choice for lawn mower decks due to its durability and resistance to chipping, scratching, and fading. The process involves applying a dry powder that is then cured under heat, creating a hard finish that can withstand harsh weather conditions and regular usage.

- Paint Coating: Traditional paint coatings can offer a good level of protection if applied properly and maintained. However, they may require frequent touch-ups and reapplication over time, especially if the mower is often exposed to moisture and debris, which can lead to peeling and rust.

- Galvanization: This method involves coating the metal with a layer of zinc to prevent rust and corrosion. Galvanized decks are highly resistant to moisture and are ideal for environments where the mower may be exposed to rain or wet grass, but they can be heavier and may require more robust support.

- Ceramic Coating: Known for its superior resistance to chemicals and UV light, ceramic coatings create a hard, protective layer that repels dirt and grass clippings. While more expensive, this coating can significantly reduce the frequency of cleaning and maintenance needed for the mower deck.

- Rubberized Coating: This type provides a flexible, impact-resistant surface that can absorb shocks and vibrations. Rubberized coatings are particularly effective in preventing scratches and dents, making them suitable for rugged terrain or heavy use.

- Vinyl Wraps: Though not a traditional coating, vinyl wraps can protect the deck while allowing for customization. They are resistant to UV rays and moisture but may not offer the same level of protection against physical damage as other coatings.

How Do Paints Differ from Polymeric Coatings for Lawn Mower Decks?

The main differences between paints and polymeric coatings for lawn mower decks relate to their composition, durability, and performance characteristics.

- Paint: Paint is typically composed of pigments, solvents, and binders, and it is designed primarily for aesthetic purposes and basic protection.

- Polymeric Coating: Polymeric coatings are advanced materials that provide superior durability and resistance to abrasion, chemicals, and UV light, making them ideal for lawn mower decks.

Paint: While paint can cover and protect the surface of a lawn mower deck, it often lacks the resilience needed for harsh outdoor conditions. It may chip, fade, or wear away more quickly, requiring more frequent reapplications to maintain appearance and protection. Furthermore, traditional paints may not adhere well to metal surfaces exposed to fuel, oil, and moisture, leading to peeling or rusting.

Polymeric Coating: In contrast, polymeric coatings form a strong, flexible film that adheres tightly to the surface of the lawn mower deck, providing a long-lasting barrier against environmental damage. They are resistant to scratches, chemicals, and UV degradation, which helps maintain the mower’s integrity and appearance over time. Additionally, polymeric coatings can often withstand extreme temperatures and moisture, making them a superior choice for protecting lawn mower decks from wear and tear.

What Benefits Do Each Type of Coating Offer for Lawn Mower Deck Durability?

The best coating for lawn mower decks provides various benefits that enhance durability and performance.

- Powder Coating: This type of coating offers excellent resistance to scratches, chemicals, and UV rays.

- Polyurethane Coating: Known for its flexibility and toughness, polyurethane provides a strong barrier against moisture and corrosion.

- Epoxy Coating: Epoxy coatings create a hard, durable surface that is resistant to wear and tear, making it ideal for protecting against heavy-duty use.

- Aluminum Coating: This coating provides a lightweight and corrosion-resistant layer that can withstand harsh weather conditions.

- Vinyl Coating: Vinyl coatings offer a smooth surface that is resistant to rust and can help reduce friction, enhancing mower efficiency.

Powder Coating: Powder coating is applied as a dry powder and then cured under heat, resulting in a hard finish that is much tougher than conventional paint. It effectively protects the mower deck from nicks, scratches, and damage from lawn chemicals, extending the life of the mower.

Polyurethane Coating: This coating is known for its excellent adhesion and resistance to abrasion. Its elasticity allows it to expand and contract with temperature changes, providing a long-lasting, flexible barrier that protects against moisture and rust while enhancing the mower’s aesthetic appeal.

Epoxy Coating: Epoxy coatings are made from a mixture of resin and hardener, creating a strong bond that protects against impact and abrasion. This type of coating is particularly effective for heavy-duty mowers that experience high wear, ensuring that the mower deck remains intact over time.

Aluminum Coating: An aluminum coating provides a lightweight protective layer that reflects heat and resists corrosion from moisture and chemicals in the grass. This type of coating is particularly beneficial in humid environments, prolonging the life of the mower deck.

Vinyl Coating: Vinyl coatings can be easily applied and provide a smooth, slick surface that minimizes grass build-up, making mowing easier and more efficient. The resistance to rust and corrosion makes it an excellent option for those looking to maintain their mower with minimal upkeep.

How Should I Prepare My Lawn Mower Deck Before Applying a Coating?

To effectively prepare your lawn mower deck before applying a protective coating, consider the following steps:

- Clean the Deck: Remove all grass clippings, dirt, and debris from the mower deck using a power washer or a stiff brush. This ensures that the coating adheres properly and prevents any contaminants from compromising the finish.

- Inspect for Damage: Check the mower deck for any cracks, rust, or other damage. Addressing these issues beforehand will ensure a smooth application and extend the life of both the deck and the coating.

- Sand the Surface: Lightly sand the mower deck with sandpaper or a sanding block to create a rough surface for better adhesion of the coating. This step helps the coating bond more effectively and reduces the likelihood of peeling or chipping.

- Wipe Down with Solvent: Use a solvent like mineral spirits or acetone to wipe down the deck after sanding. This removes any dust or oils that may have accumulated, ensuring that the surface is clean and ready for the coating.

- Mask Off Areas: Use painter’s tape to mask off any areas that should not be coated, such as the engine or wheels. This helps to achieve a clean finish and prevents coating overspray that could lead to further maintenance issues.

What Tools and Materials Do I Need for Proper Preparation?

To properly prepare for coating your lawn mower deck, you will need several essential tools and materials.

- Protective Gear: Safety goggles, gloves, and a mask to protect against dust and fumes during the preparation process.

- Scraper or Wire Brush: Tools to remove old paint, rust, and debris from the mower deck, ensuring a clean surface for the new coating.

- Sandpaper or Power Sander: Used to smooth the surface and remove any remaining imperfections, promoting better adhesion of the new coating.

- Cleaning Solution: A degreaser or mild detergent to thoroughly clean the mower deck and remove any grease, dirt, or contaminants.

- Primer: A rust-inhibiting primer that prepares the surface, providing a better base for the final coating and enhancing its durability.

- Coating Material: The best coating for lawn mower decks could be a specialized paint or sealant designed to resist moisture and abrasion, ensuring long-lasting protection.

- Paint Sprayer or Brush: Depending on your preference, either a sprayer for an even coat or a brush for detailed application, allowing for seamless coverage of the deck.

- Drop Cloth or Tarp: To protect the surrounding area from overspray and drips during the application process.

- Masking Tape: Useful for covering parts of the mower that should not be coated, helping to achieve clean lines and prevent overspray.

Protective gear is essential to ensure your safety while working with chemicals and abrasive tools. The scraper or wire brush will help you effectively remove any old coatings or rust, setting the stage for a fresh application. Sandpaper or a power sander will smooth out the surface, which is crucial for achieving a professional finish.

A cleaning solution will ensure that the surface is free from contaminants that can affect the adhesion of the coating. Applying a primer is a critical step as it not only bonds with the metal but also provides a layer of protection against rust. Choosing the best coating for lawn mower decks will contribute to the longevity and appearance of your mower.

Whether you opt for a paint sprayer or brush, using the right application method is important for an even and durable finish. Finally, protecting your workspace with a drop cloth and using masking tape will help keep your project area organized and clean. These tools and materials combined will ensure that your lawn mower deck is properly prepared for coating.

How Do I Apply Coating to My Lawn Mower Deck Effectively?

To effectively apply a coating to your lawn mower deck, consider the following methods and materials:

- Preparation: Properly preparing the mower deck is crucial for coating adhesion and durability.

- Choosing the Right Coating: Selecting the best coating for your lawn mower deck can enhance protection and longevity.

- Application Technique: Using the right application technique ensures an even and effective coating layer.

- Curing Time: Allowing sufficient curing time is essential for the coating to bond properly.

Preparation: Start by cleaning the mower deck thoroughly to remove grass clippings, dirt, and rust. Use a wire brush or a power washer for stubborn debris and allow the surface to dry completely before applying any coating to ensure optimal adhesion.

Choosing the Right Coating: The best coating for a lawn mower deck typically includes options like spray-on bed liner, automotive paint, or specialized lawn mower deck coatings. Look for products that are resistant to moisture, chemicals, and UV rays to ensure long-lasting protection.

Application Technique: When applying the coating, use a spray can or a brush to ensure an even layer across the entire surface. Apply multiple thin coats rather than one thick coat, allowing each layer to dry before adding the next to prevent drips and runs.

Curing Time: After applying the coating, allow it to cure according to the manufacturer’s instructions, which usually involves waiting 24-48 hours before using the mower. This step is critical as it ensures that the coating has fully adhered and hardened, providing maximum protection for the deck.

What Maintenance Practices Are Essential for Coated Lawn Mower Decks?

Essential maintenance practices for coated lawn mower decks ensure longevity and optimal performance.

- Regular Cleaning: Keeping the mower deck clean is crucial to prevent grass buildup and corrosion. Use a hose or a soft brush to remove clippings and debris after each use, as accumulated material can lead to rust and hinder performance.

- Inspection for Damage: Regularly inspect the coating for any chips, scratches, or wear. Addressing these issues promptly by touching up the coating can prevent further degradation and maintain the deck’s protective qualities.

- Proper Storage: Store the mower in a dry, sheltered area to avoid exposure to moisture and harsh weather conditions that can damage the coating. Using a mower cover can provide additional protection against elements that may compromise the integrity of the coating.

- Seasonal Waxing: Applying a wax or sealant specifically designed for lawn mower decks can enhance the protective coating. This practice helps create a barrier against water, grass sap, and other damaging substances, prolonging the life of the coating.

- Avoiding Overuse of Chemicals: Minimize the use of harsh chemicals or solvents for cleaning the deck, as they can degrade the coating. Opt for mild detergents and water to maintain the surface without risking damage to the protective layer.

How Can I Prevent Damage to My Lawn Mower Deck Coating Over Time?

Routine Inspections: Regularly inspecting the mower deck for signs of wear or damage allows for timely repairs and maintenance to extend the life of the coating. Catching issues early, such as chips or scratches, can prevent further damage and provide an opportunity for touch-ups or re-coating as necessary.

Related Post: